As a newly subscribed member of The Papermakers and Artists Qld, I went along to a hands-on paper making day unsure what to expect.

I knew I needed to bring some botanical fibre (so I chopped up some of my lemongrass bush trimmings), lunch and a baked treat to share, along with hat, sturdy shoes etc. We set up tables outside and set about the business of making paper.

The communal fibre donations were bagged and then cooked in a boiler full of water spiked with caustic soda for a couple of hours to help dissolve the organic soft planty bits and loosen the cellulose fibres.

While this was cooking, we mixed vats with pre-prepared pulp of all sorts – lemon grass, banana leaf and stem, cotton, mounting board and other botanicals, then with a trusty A5 mould and deckle we scooped and twizzled, shaked and dripped to form sheets of matted fibre, couching carefully on to damp cloth and layering as we went.

Then, with a nice stack of couched wet pulpy sheets, it was off to the hydraulic press to squoosh the water out. Some of my sheets I left to dry on their felts, some I transferred to fibro sheets to dry flat. then it was back to make more.

I found an A3 mould, and struggled to make a full complete sheet, but the larger size is interesting. After a couple of goes I went back to an A4 mould, making some lovely sheets with decorative inclusions.

When the communal fibre was cooked, it was rinsed a number of times, the strong alkali being neutralised by vinegar, it was then transferred into the beater (a “Hollander Beater”) – an amazing bit of kit that circulates a puddle of suspended gloop and vigorously beats it, spreading and opening up the fibres, making a soft cloud-like suspension and tangle of finely divided fibre that could then be used to make paper.

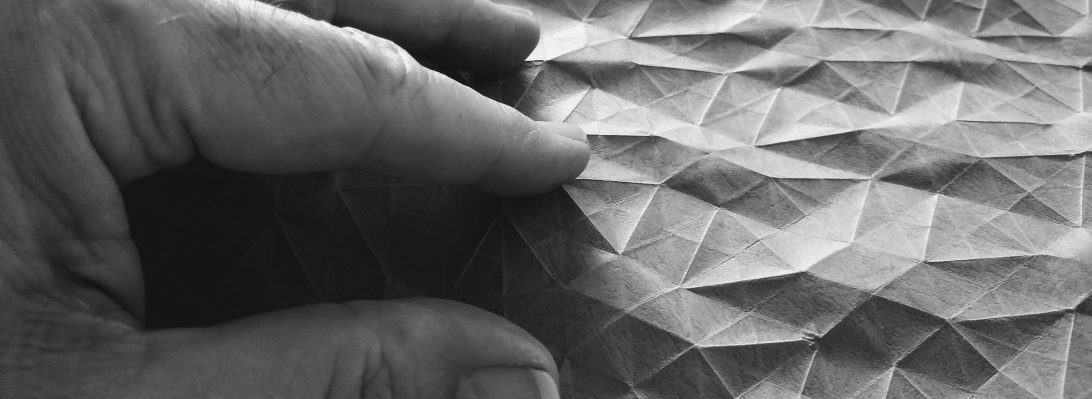

It was a terrific day, I learned lots, and look forward to being able to fold/use my collected papers. I chose to make a bunch of different ones, some are thick, some thin, some soft, some crispy – they will be fun to experiment with. All in all I now have a much better idea of the process, and look forward to learning more.