One of many goals, long term, is for me to make and fold my own paper. By “make paper” I mean collect, process and form sheets from pulp. I clarify because one school of thought around “making paper” is laminating or treating existing sheets – I do that also, but yeah, there is a distinction.

I attended a workshop out back of Gympie with Dion Chandler, using my newly acquired mold and deckle, and pulled (get the lingo 😛 ) A3 sheets – by the end I got pretty consistent at it but need more practice.

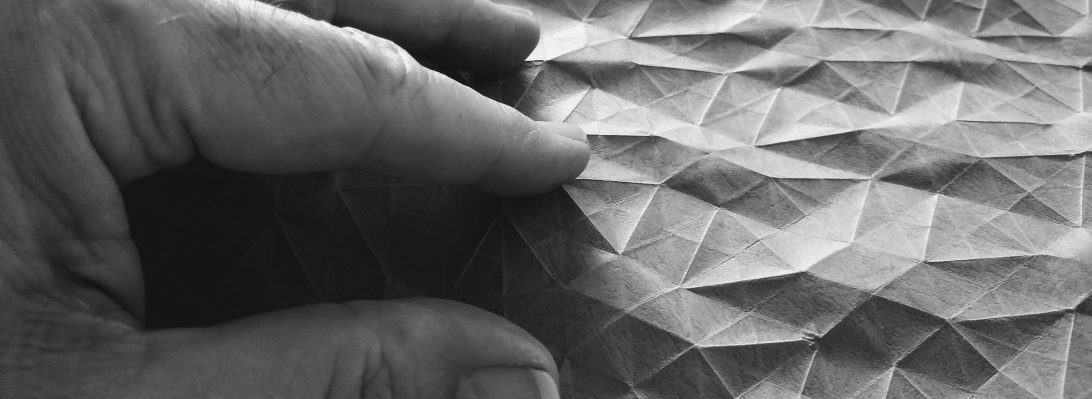

I ended up making A3, A4 and a smaller “letter” size”, love the deckle edges and the structure of the sheets. I have also Methyl Cellulosed some and, so long as I apply the MC to the paper (and not the glass I am sticking it to) then the sheets come away crisp and sturdily hold folds crisply as well.

That workshop we were pulling from a vat that started mostly with cotton pulp, and gradually had recycled kozo (mulberry) to it – quite a resilient mix. the resultant sheets are precious and wonderful.

I had been folding pentagon roses so decided to inflict a pentagon rose (bloom, calyx, stem, leaf) on a whole sheet and a slightly mangled one, and the result is stunning – I just love it.

The sheets were formed with well-beaten pulp, were quite thin when pulled, and were pressed well – the pressure they are subjected to while drying helps determine the tensile strength (via hydrogen bonds), and being dried under weight also helps.

I have been amassing the equipment necessary to make more, and also have a good collection of fibres including Kenaf, Cotton linters, Kozo and others, meaning I will be able to decide (to a limited extent) on the characteristics of the paper I want before I then make it. All very interesting.